Introduction of Spedent® TC+ Skeleton Oil Seal

Product Introduction

Skeleton oil seals are widely used sealing components in industrial equipment. They are commonly used to prevent leakage of liquids or gases to protect various components of equipment. Here are the product introductions for skeleton oil seals:

Definition

A skeleton oil seal is a type of sealing component composed of a metal skeleton and rubber sealing lips, used to prevent leaks of axial liquids, oil, and water, and to prevent the entry of dust, mud, and small particles into equipment.

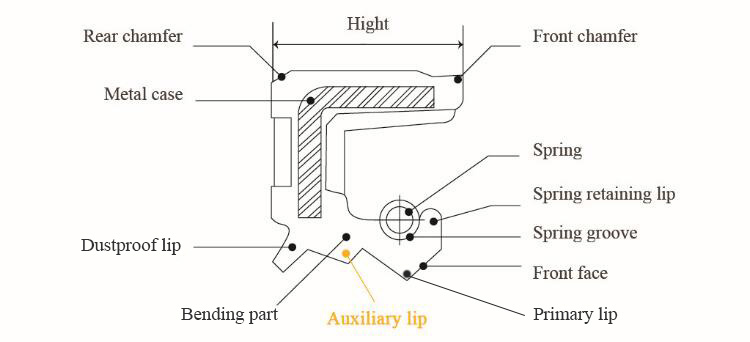

Structure

The structure of a skeleton oil seal consists of several parts, including jacket, spring, sealing lips, filler, etc. The skeleton is usually made of metal material to ensure its rigidity and durability. The sealing lip is made of high-quality rubber material to ensure its sealing performance for liquids and gases.

Types of products

Skeleton oil seals are usually classified according to different working conditions, industrial equipment, and liquid media requirements. Special materials are also available for production, particularly for different media. Common types of products include oil seals, gas seals, water seals, dust seals, etc.

Advantages

Skeleton oil seals have many advantages. Firstly, they can effectively prevent fluid leakage and protect various components of equipment. Secondly, skeleton oil seals usually use high-quality rubber materials, making them highly abrasion-resistant and oxidation-resistant. Finally, this type of sealing component has the advantages of compact structure and easy installation.

Applications

Skeleton oil seals have been widely used in industrial equipment. They are commonly used in various industries such as automobiles, agricultural equipment, and machinery. Due to their wide range of applications and advantages, the market prospects for skeleton oil seals are broad, and they have won the trust and praise of many customers.

In summary, skeleton oil seals are efficient sealing components with many advantages and are suitable for many different industries.