Spedent oil seals are typical of oil seals and most oil seals refer to a skeleton oil seal. Most of the functions of an oil seal are to isolate the part to be lubricated from the outside environment to avoid leakage of lubricant. The skeleton is like the steel reinforcement in a concrete member, playing a reinforcing role to keep the oil seal in shape and tension. They can be divided into single lip skeleton oil seals and double lip skeleton oil seals according to their structure. The secondary lip of the double-lip oil seal of the skeleton plays the role of dustproof, preventing external dust and impurities from entering the machine. According to the type of skeleton, it can be divided into internal package skeleton oil seal, exposed skeleton oil seal and installation configuration oil seal. According to the working condition, it can be divided into rotary skeleton oil seal and reciprocating skeleton oil seal. They are used in gasoline engine crankshaft, diesel engine crankshaft, gearbox, differential, shock absorber, engine, axle, etc.

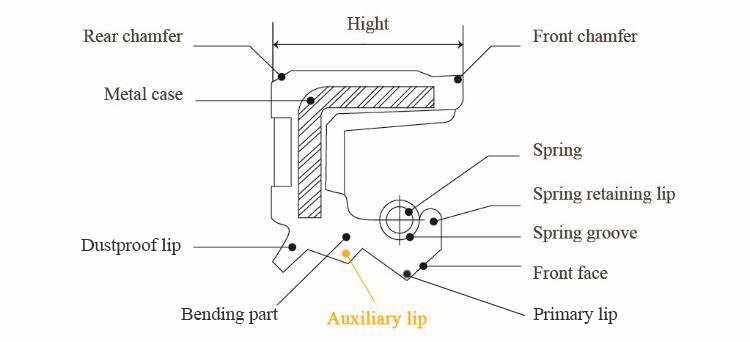

SPEDENT New TC+ skeleton oil seal added a micro-contact auxiliary lip in the middle, this design can be protect and support the primary lip, makes it not turn over and swing easily, and sealing strength of the lips in more centralized, which increases stability of sealing and prolongs its life.

Installation method of Spedent Oil Seal:

One side of the spring faces inward (facing oil), and the side with specifications written on it faces outward.

1. Spedent oil seal is a typical representative of oil seal. Most oil seals refer to the skeleton oil seal. Much of the function of the oil seal is to isolate the part of the transmission component that needs to be lubricated from the output component so that the lubricant does not leak. The skeleton is like the steel reinforcement in a concrete member, acting as a reinforcement to keep the oil seal in shape and tension. According to the structure, it can be divided into single lip skeleton oil seal and double lip skeleton oil seal.

2. The secondary lip of double-lip skeleton oil seal plays the role of dustproof, preventing external dust and impurities from entering the machine. According to the type of skeleton, it can be divided into internal skeleton oil seal, exposed skeleton oil seal and installation configuration oil seal. According to the working condition, it can be divided into rotary skeleton oil seal and reciprocating skeleton oil seal. They are used in gasoline engine crankshaft, diesel engine crankshaft, gearbox, differential, shock absorber, engine, axle, etc.

Precautions for Spedent Oil Seals:

When installing the oil seal, pay attention to ensure the residual glue, oil, rust spots, burrs, etc. The installation hole slot of the oil seal and the end face of the equipment have been cleaned. Installation direction of open oil seal:The crown of the oil seal (the side of the spring groove) faces the sealing cavity, do not install it upside down. When installing the oil seal, it is important to ensure that the cleft is above the bearing.

The roughness of the axial surface where the seal lip is located must be less than or equal to 1.6μ; in addition, it is important to note that a poorly tight oil seal is a key factor in oil leakage. Important officials have a groove formed by the developmental changes in wear, which cannot be sealed even with a new oil seal, because the contact pressure between the oil seal lip and the shaft is reduced, resulting in too small an interference between the oil seal lip diameter and the shaft diameter after installation.

Post time: Jun-09-2023